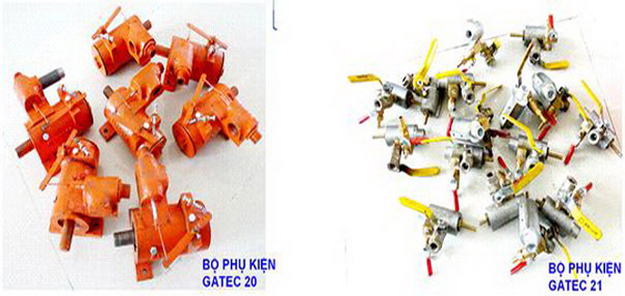

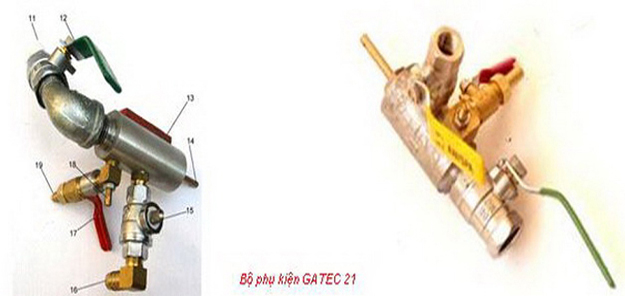

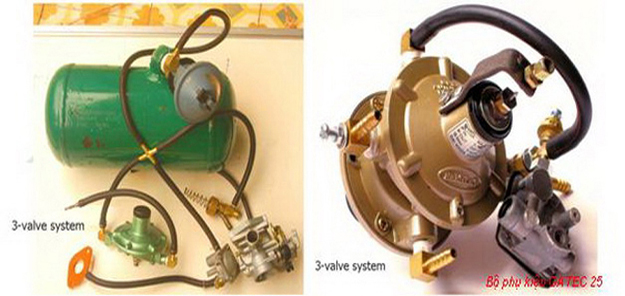

GATEC cung cấp phụ kiện

động cơ nhiên liệu khí (Biogas,

LPG, CNG, Hydrogen, khí rác...)

- 0914 240 345 (Trâm)

- 0932 533 059 (Vũ)

Email: gatec@dongcobiogas.com

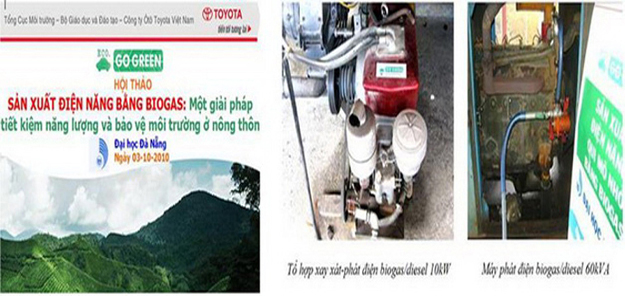

- Động cơ Biogas-Diesel: Xem tại đây

hoặc: Xem tại đây

- Động cơ 100% Biogas: Xem tại đây

- Lắp đặt động cơ Biogas: Xem tại đây

Động cơ sử dụng nhiên liệu khí linh hoạt trong

hệ thống năng lượng tái tạo hybrid biomass-solar

GATEC

Đại học Đà Nẵng

Hệ thống năng lượng tái tạo hybrid (HRES) khắc phục được những nhược điểm của hệ thống chỉ sử dụng một nguồn năng lượng tái tạo duy nhất. Công suất của HRES ít bị dao động theo điều kiện thời tiết, khí hậu, mùa vụ…

Việt Nam có tiềm năng lớn về năng lượng mặt trời, năng lượng gió, năng lượng sinh khối. Việc kết hợp sử dụng các dạng năng lượng tái tạo này trong HRES là giải pháp hữu hiệu để phát triển ứng dụng năng lượng tái tạo trong chiến lược chuyển đổi năng lượng.

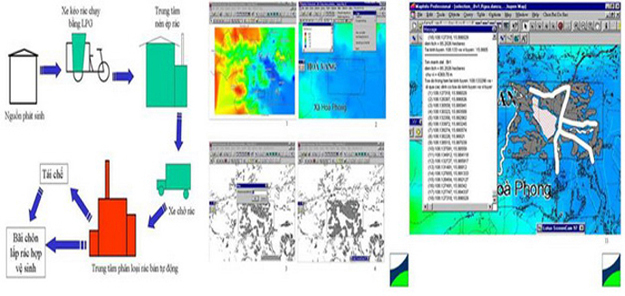

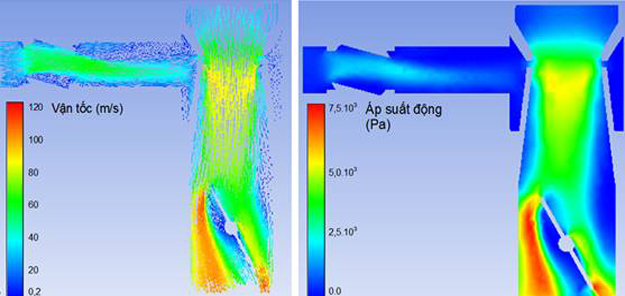

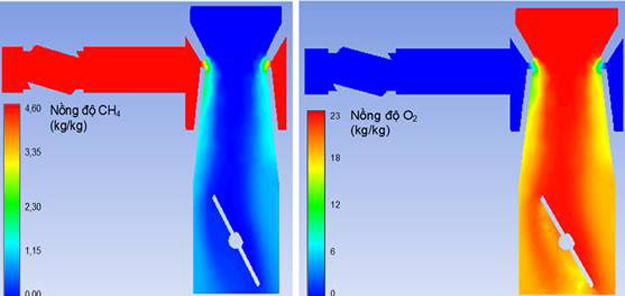

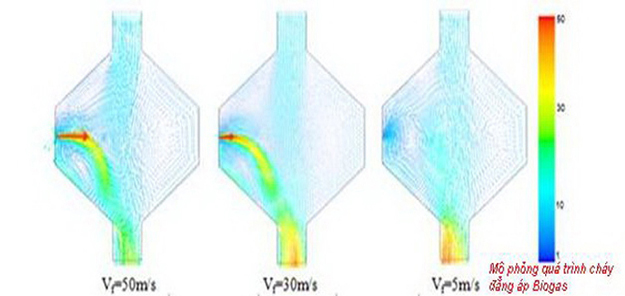

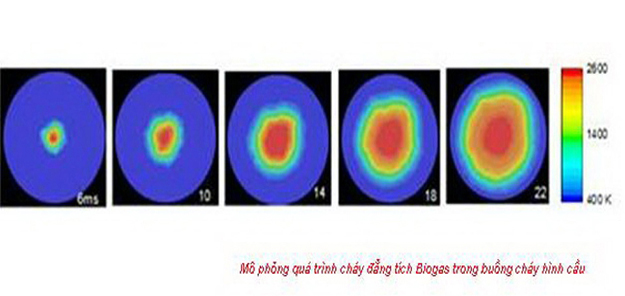

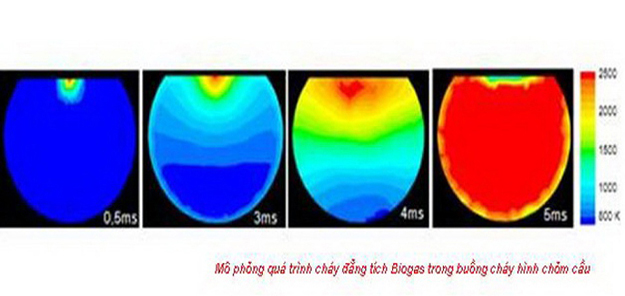

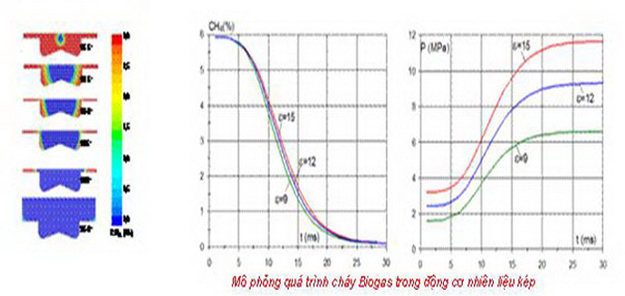

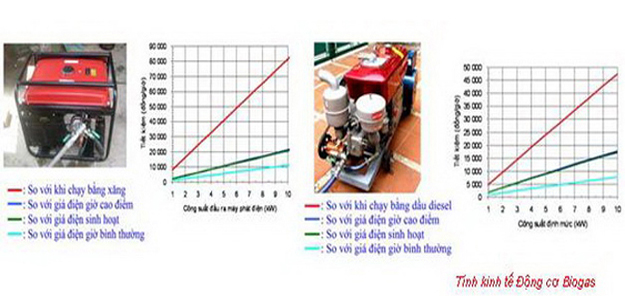

Trong HRES, động cơ đốt trong sử dụng nhiên liệu khí được xem là nguồn ổn định và duy trì công suất của hệ thống. Biomass được chuyển hóa thành biogas (hầm biogas) hay syngas (lò khí hóa). Khi công suất của hệ thống năng lượng mặt trời, năng lượng gió lớn hơn công suất phụ tải thì phần công suất dư được dùng để sản xuất hydrogen. Khi công suất điện mặt trời, điện gió bị gián đoạn hay thấp hơn công suất phụ tải thì động cơ sử dụng biogas-syngas-hydrogen phát điện để bù công suất.

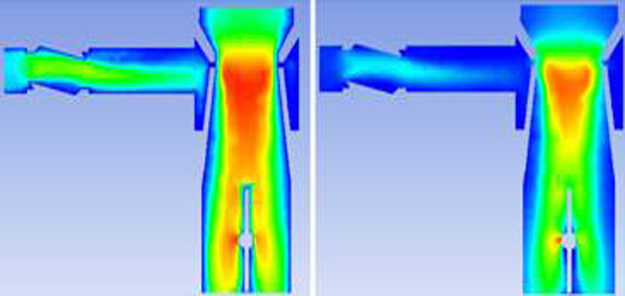

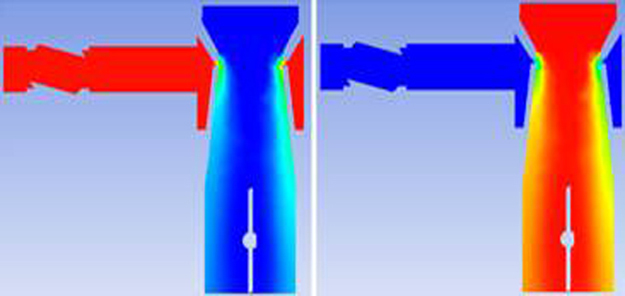

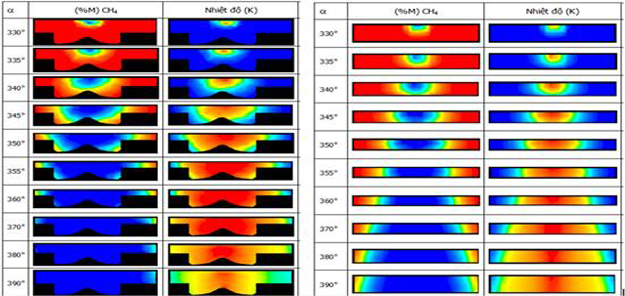

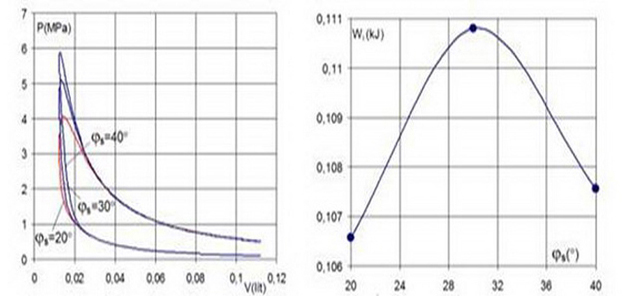

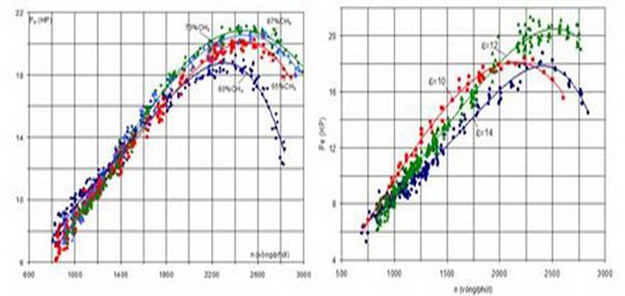

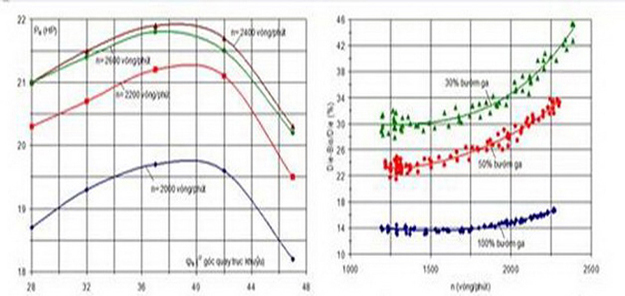

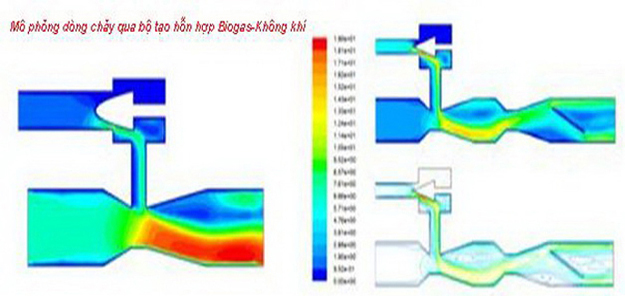

Do thành phần nhiên liệu biogas-syngas-hydrogen thay đổi trong phạm vi rộng nên động cơ cần được điều chỉnh linh hoạt để cải thiện tính năng công tác. Điều này có ý nghĩa quan trong khi động cơ sử dụng hỗn hợp nhiên liệu có chứa syngas, nhiên liệu có tỉ lệ không khí/nhiên liệu thấp hơn rất nhiều so với các loại nhiên liệu truyền thống.

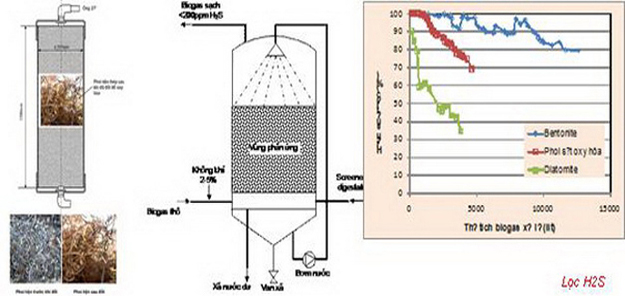

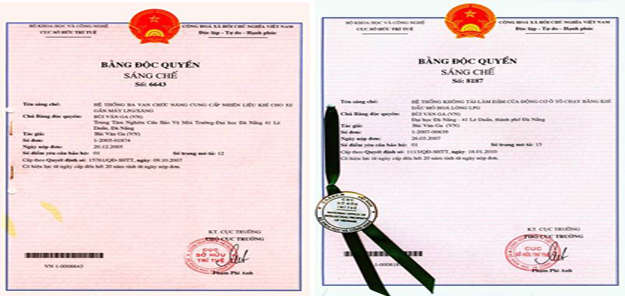

Nhóm nghiên cứu GATEC của Đại học Đà Nẵng đã và đang nghiên cứu hệ thống HRES biomass-solar từ khâu chuyển hóa chất thải rắn thành RDF đến cải tạo động cơ truyền thống thành động cơ sử dụng nhiên liệu khí linh hoạt.

Bài viết mới

Liên kết các đơn vị

CÁC CSGD ĐẠI HỌC THÀNH VIÊN

|

|

Đại học Đà Nẵng 41 Lê Duẩn, TP Đà Nẵng |

|

Trường Đại học Bách khoa 54 Nguyễn Lương Bằng, Quận Liên Chiểu, TP Đà Nẵng |

|

Trường Đại học Kinh tế 71 - Ngũ Hành Sơn - TP. Đà Nẵng |

|

Trường Đại học Sư phạm 459 Tôn Đức Thắng - Liên Chiểu - Đà Nẵng |

|

Trường Đại học Ngoại ngữ 131 Lương Nhữ Hộc, Đà Nẵng |

|

Trường Cao đẳng Công nghệ

48 Cao Thắng - Đà Nẵng

|

|

Trường Cao đẳng Công nghệ Thông tin

Hòa Quý - Ngũ Hành Sơn - Đà Nẵng

|

|

Phân hiệu ĐHĐN tại KonTum 129 Phan Đình Phùng, Kon Tum |

|

Khoa Y Dược 41 Lê Duẩn, Đà Nẵng |

|

Khoa Giáo dục Thể chất 62 Ngô Sỹ Liên, Liên Chiểu, Đà Nẵng |

|

|

Khoa Quốc tế 41 Lê Duẩn, Đà Nẵng |

|

Tầng 9 Khu B – 41 Lê Duẩn

|

|

Trung tâm Thông tin Học liệu 91a Nguyễn Thị Minh Khai - TP Đà Nẵng |

|

Trung tâm Phát triển Phần mềm 41 Lê Duẩn, Đà Nẵng |

|

Trung tâm Đào tạo Thường xuyên 158 Lê Lợi - Đà Nẵng |

|

Trung tâm Thể thao 62 Ngô Sỹ Liên, Liên Chiểu, Đà Nẵng |

|

Trung tâm nghiên cứu và ứng dụng năng lượng thay thế 54 Nguyễn Lương Bằng, Đà Nẵng; Tel: 0913 459 649 |