SMALL BIOGAS-DIESEL DUAL FUEL ENGINE

Using fossil fuel in the past decades has caused grave damage to environment, especially in increasing of Green House Effect gas in combustion products. If there is no prevention of increasing CO2, sea level will increase and some land areas will disappear on the map, millions of people will loose their houses, and human beings will face with more horrible natural disasters.

Solar energy is the most durable in time scale of the Solar system. A successful research and rapidly applying of results in technology solutions on renewable energy will help to solve two serious vital problems: energy and environment.

In our country, there is more than 80% of population living in rural areas. Organic wastes from agricultural production are suitable for producing biogas. However, due to individual scattered agricultural production, biogas plants are built with small size. They are suitable to small capacity equipment serving for production and life in rural areas in which internal combustion engines running with biogas are now in great demand.

This work focuses on biogas supplying system for stationarydual fuel engines. The supplying system consists of H2S filter, CO2 absorber and speed regulator.

Filtrating H2S using iron shavings and using water to absorb CO2 is a simple, low cost and effective solution, suitable for households in rural areas. Biogasafter running through this filtration system can be used as fuel for internal combustion engines.

A biogas/petroleum conversion kits for Diesel engine have been suggested. With these conversion kit, the stationary engines can generate electricity. They consume about 1m3 biogas to produce 1kWh electricity and contribute to reduction of emission of 1kg CO2. The voltage fluctuation is about 5% of the normal voltage value with transition time is about 2s.

1. Introduction

Energy is one of the world’s most critical issues in the 21st century. As fossil fuel resource is depleting rapidly, energy security has become more sensitive in international affairs. Continuing increase in crude oil price in recent years (over 140USD/barrel in May 2008) poses threads to the stability of the world’s economy, particularly the economies in Southeast Asian region.

In the other hand, air pollution caused by burning fossil fuels (coal, oil, and natural gas…) have caused impacts on human being and the environment for decades. Combustion product contains pollutants that are very harmful to human health such as carbon monoxide (CO), hydrocarbons (HCs), nitrogen oxides (NOx), sulfur oxide (SO2), soot etc… Especially carbon dioxide (CO2), the main product of combustion, is a green house effect gas that significantly contributes to global warming. A lot of international efforts and initiatives has been made to reduce greenhouse effect gas emissions for controlling the phenomenon of climate change. ASEAN member countries have commitments to implementation of Kyoto Protocol under UN Framework Convention on Climate Change and are already making steps towards emission reductions, particularly through Clean Development Mechanism. The utilization of sustainable and renewable energy is apparently a effective measure to achieve CO2 emission reduction targets and combat with the global warming.

Research on using of renewable energy as a alternative source of energy has captured attention of scientists for decades, especially since the world’s oil crisis in 1973. Biogas, a neutralizing CO2 fuel, has double interest: energy saving and environment protection. Biogas is a product of decomposing organic substances in anaerobic conditions. Organic substances can often be plants (trees, straws etc.) or animals (animal wastes, by-products from food processing…), and wastes from breeding. CO2 generated by burning biogas will be absorbed by new plants; therefore, CO2 amount in atmosphere will be balanced. There are two main sources of biogas produced: one from biogas digesters (tanks) and the other from the organic substance fermentation under anaerobic conditions in landfills. Biogas contains mainly CH4 (50-70%) and CO2 (25-50%) and other impurities such as H2S. If biogas is refined from impurities, we will have a fuel with the same properties as natural gas. Developed countries such as USA, France, Germany, Denmark etc… use biogas from landfills to generate electricity. In developing countries, biogas production technology for household use has become popular, particularly in India, China and ASEAN countries. In the meantime, developing countries has also piloted or employed technologies of utilizing biogas form landfills for power generation.

Over the past ten years, energy from biogas has become widely used in Viet Nam. Biogas production processes have been improved to achieve higher efficiency. Traditional biogas tanks (digesters) built with bricks and concrete often corroded by acids, which causes gas leakage problems. Recently, The University of Danang have been successfully developed super durable composite biogas tanks to overcome such problems. This new type of digesters made of composite material is resistant to acid corrosion, and thus can avoid gas leakage. It also allows to thrust out wastes without opening the cover manually. Thanks to high biogas pressure, composite tanks are able to self-regulate pressure, so that the use of safety valve is unnecessary. With the same volume as brick or concrete tanks, composite ones can supply more biogas to generate power for a household use such as lights, boilers, or small electricity generator. Especially with composite tank, it requires lesser time for installations. This kind of tanks is welcomed by many farmers thanks to its higher effectiveness.

Else where in Viet Nam, biogas production technologies have been well developed. Many projects supported by international funds has significantly contribute to success of biogas applications across the country. In 2006, a collaboration project on biogas production between Viet Nam and Netherlands was awarded the Environment Prize of the United Nations.

Today, the utilization of energy from biogas has helped in dealing with major issues related to environment protection and energy use in rural areas where more than 80% Vietnamese population live. At present, biogas is used mostly for cooking. Direct combustion is the simplest method of biogas energy utilization. However growing demand for household energy further pushes up the development of biogas utilization in producing power for working machines used in argo-based industries such as pumps, mills, regrigerators… Development and applications of technologies to use biogas as a fuel for small power internal combustion engines will make an important contribution to meeting the demand for power, raising income and protecting local environment in rural areas of Viet Nam as well as other ASEAN Countries.

United Nations Climate Change Conference in Bali, Indonesia in December 2007, confirmed the dangers of global warming faced by human beings, and appealed the governments of both developed and developing countries work together to enhance the use of renewable energy in order to reduce greenhouse gas emission and combat climate change. Technology development and application of biogas on small engines in rural area, in particular and its utilization for power generation in general will make contributions to realization of such appeal.

In the previous works we have presented the results of our research of application of biogas on spark ignition engines. The present paper will focus on dual fuel engine running on biogas.

2. Theoritical calculation

The combustion of hydrocarbon in general can be expressed by the following model:

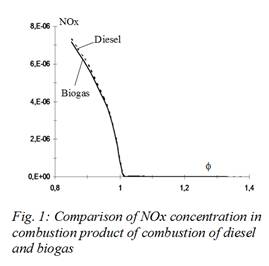

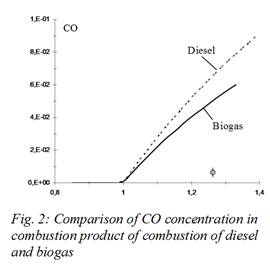

The combustion product is assymed in thermodynamique equilibrum state. This equation system is solved by calculation code which has been presented in [4]. The figure 1 and 2 present the concentrations of NOx and CO in combustion product of diesel and biogas fuel. The results show that the CO emission is reduced more than 20% when the engine runs on biogas in comparison with diesel case. The difference in NOx emission is not considerable.

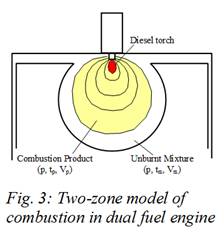

The application of the model in combustion chamber of engine needs law of flame propagation. This law in dual fuel engine is similar to that of spark ignition engine but the electric spark is replaced by a fire torch (figure 3). In fact, at the end of compression of dual fuel, an injection is introduced and the mixture is ignited instead of electric spark. The flame propagation is the same as gasoline engine. The difference here is at the form of original ignition source. So we can apply the two-zone model [3] to calculate the combustion in combustion chamber of dual fuel engine. In the present paper, the form of diesel torch is determined by model of diffusion flame. This form is changed according to fuel injection quantity. The flame propagation is then calculated with following assymptions:

– The mixture biogas-air is homogenous

– The flame form is affine

– Normal flame velocity is constant

The mixture and the combustion product are separated by flame front. The thermodynamic state of fluid in combustion chamber is represented by following equation system:

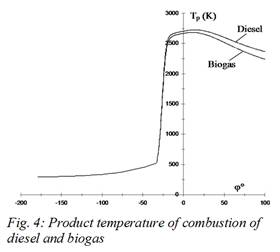

The calculation is applied to Kubota engine GX125-2X-NB-GE whose compression ratio is 24. The bore and the stroke are respectively 90mm and 94mm. Figure 4 shows comparison of variation of combustion temperature of product in case of diesel and biogas running. In the calculation, we assyme that the injection is maximum and the mixture is homogenous in case of diesel. Product temperature of biogas case is lower than that of diesel case essentially due to the impurities of biogas. The lower temperature conducts to lower pressure in the combustion chamber in case of biogas (figure 5).

Figure 6 presents the variation of pressure in combustion chamber with different quantities of diesel injection. The biogas charge is 80% of the maximum quantity. The diesel injection quantity varies from 2% to 15% of maximum injection. The maximum pressure increases about 20% when diesel injection quantity varies from 2% to 15%. This remarque is useful for power control of biogas/diesel dual fuel engine. In fact in case of poor biogas, we can increase the diesel injection to insure the requirement of utility power.

3. Pratical realization

The use of biogas as a fuel for engines requires treatment of produced gas to remove impurities (known as biogas filtration), of which H2S and CO2 are major substances. It is also necessary to develop biogas/petroleum fuel conversion kits to apply this renewable fuel on internal combustion engines.

– H2S removal process:

To remove H2S from biogas stream, simple method of adsorption by iron oxides is employed [1], [2]. In preparation of iron oxides as adsorbent, ion scraps are pre-treated by oxidization to form the coated iron oxides layer. The formed iron oxides are the mixtrure of FeO, Fe2O3, Fe3O4. Pre-treated iron scraps are mixed up with wooden scraps and sawdust in the ratio 1:1 and then loaded into an adsorption vessel. With the diameter of 0.2m and height of 1.5m, a PVC vessel is capable of containing 8 kg adsorbing material and processing 0,86 m3 biogass per hour. Averaged pressure loss through the H2S removal column is about 0.3mbar during operation [6].

– CO2 scrubber:

Liquids with increased solubility for CO2 are typically chosen over water in CO2 scrubbing process, but the principal advantages of water as an absorbent are its availability and low cost. Absorption of acid gas by water produces slight corrosive solutions that can be harmful to equipment if not controlled. CO2 and water countercurrent contact with each other in a scrubber. A neutral material layer consisting of brickbats, woodchips and gravels as a packed column is fitted into the scrubber by a perforated plastic sheet to intensify the gas-water contact. In our experiment, the scrubber operates at biogas flow rate of 0.86 m3/h, CO2 concentration at inlet is 36.47%, and 19.22% at outlet of biogas stream. CO2 removal efficiency reaches 47.30%. Pressure drop through the packed column is about 5mbar [6].

– Biogas supplying system for small power engines:

After such removals of impurities, biogas meets the requirement of a fuel for internal combustion engines.

Figure 7 presents different components of biogas system. Biogas is produced in digester manufactured by nylon bag. After passing H2S removal, biogas is stored in a nylon bag. The pressure of biogas in the bag is about 40mmH2O. The bag volume is calculated according to digester free volume.

In the previous work, a system of feeding biogas into small spark ignition engines driving generator has designed [5], [6]. The system has to meet the basical requirements of maintaining invariant frequent (50Hz) of electric current output in any loading regime [9]. For spark ignition engines running on biogas, we can apply LPG/gasoline conversion kit [8] with some modifications. The present work is focused on biogas supplying system of diesel engine.

Different possibilities of biogas supplying system to diesel engine have been presented in [10], [11]. Engine load in function of engine speed can be controlled by embedded system using signal of electrical tension or engine speed. Original regulator of the engine is no change. The conversion from diesel engine to dual fuel engine is thus simple but the system is not reliable in humid medium.

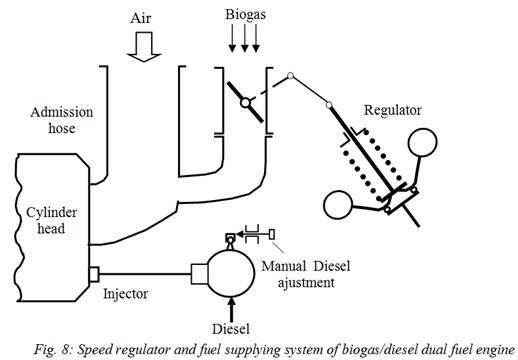

In the present work, we use mechanical regulator. The fuel supplying system of the engine is presented on figure 8. Biogas supplying pipe is connected to admission hose. The pump injection is disconnected from regulator. A new liaison is established between regulator and biogas control valve. A manual diesel ajustment is added to control diesel injection. When the engine running on biogas, we only need a little quatity of diesel (about 2% normal injection) for ignition. Constant engine speed is controlled automatically by regulator.

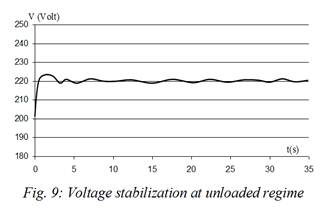

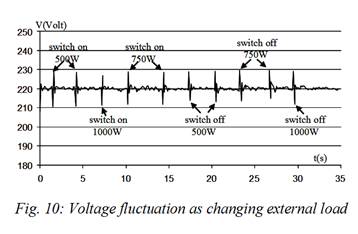

The variation of output voltage of the generator is shown on figure 9 and figure 10. In no load regime of the generator, after a short transition period of about 3s, the output voltage is stable around its normal tension. When different loads (bulbs, pumps) are switched on and switch off, the tension returns to its stable value after about 2s of transition. The voltage fluctuation is about 5% of normal voltage. It is satified the requirement of electricity production quality.

– Economy impact

The engine consumes about 1m3 of biogas to produce 1kWh of electricity.

The 5kW diesel engine consumes 10 liters of petrol in 6 hours. If it runs 6h/day on biogas, the owner can save 2 millions VND/month or 24 millions VND/year.

The owner can take enough money of investment for the biogas conversion kit after 2 months of function.

If we use 10,000 similar biogas engine groups, we can save 240 billiards VND per year.

– Environment impact

CO2 emission of combustion diesel fuel is 2.64kg/liter.

The above 5kW diesel engine runs 6h/day emits 26.4kg CO2 per day or 9.5 tons CO2 per year. Thus the production of 1kWh electricity by biogas will contribute to reduction of emission of 1kg CO2.

So, if the engine runs on biogas, we can reduce CO2 emission about 9.5 ton par year.

If we use 10.000 similar biogas engine groups, we can reduce 95.000 tons CO2 emission per year. This is considerable contribution to global warming mitigation.

4. Conclusions– Biogas is great potential energy in rural area of Vietnam. The use of this kind of energy will be an important contribution to resolving of energy-environment problem of the country.

– Biogas after removing H2S can satisfy the requirements of engine fuels. The power of engine when running in biogas can reach up to 90% of power when running on diesel.

– Mechanical speed regulator controlling biogas flow which is modified from original speed control of the engine can allow a stabilization of output voltage with fluctuation about 5% normal value and transition time is about 2s.

– For producing 1kWh electricity, the biogas/diesel dual fuel engine consumes about 1m3 of biogas and it contributes to reduction of emission of 1kg CO2

REFRENCES1. Hydrogen sulfide removal from anaerobic digester gas. Agricultural Wastes, Volume 11, Issue 3, 1984, Pages 167-179.

2. Biogas Utilization Handbook, published by the Environment, Health and Safety Division, Georgia Tech Research Institute, Atlanta, Georgia, 1988.

3. Bui Van Ga, Tran Van Nam, Le Van Tuy: Numerical code for combustion calculation in spark ignition engines. Journal of Science and Technology, No 36+37/2002, pp. 131-137

4. BUI VAN GA: Combustion: Modeling and experiment. Proceedings of Conference on 25th Anniversary of Mechanic Institute, pp. 38-44, Hanoi, 8-9 April 2004

5. BUI VAN GA, NGO VAN LANH, NGO KIM PHUNG, VENET CEDERIC: Testing of biogas on motorcycle engine. Review Science and Technology, The University of Danang, No.1(18), pp. 1-5, 2007

6. BUI VAN GA, NGO VAN LANH, NGO KIM PHUNG: Purification of biogas for fueling internal combustion engine. Review Science and Technology, The University of Danang, No 4-2007

7. BUI VAN GA, TRAN VAN NAM: Combustion of LPG-Air Lean Mixture: A solution for pollution reduction of motorcycles in Vietnam. The 6th General Seminar of the Core University Program “Environmental Science and Technology for sustainability of Asia, Kumamoto, Japan, 2-4 October 2006, pp. 361-367

8. BUI VAN GA: Patent 5940 “LPG/gasoline conversion kit for motorcycles” National Office of Intellectual Property, 2006.

9. NHAN HONG QUANG: bi-fueled reciprocating engines – an effectively solution for renewable energy utility and environmental protection in the vietnamese rural areas.Journal of Science and Development No 127-2007, pp. 30-37, 2007

10. BUIVANGA, TRUONG LE BICH TRAM, TRUONG HOANG THIEN, LE MINH TIEN: Biogas Supplying System for Small Power Engine. National Conference on Fluid Mechanics, Hue, 21-23 July, 2007

11. BUI VAN GA, LE MINH TIEN, NGUYEN VAN DONG, NGUYEN VAN ANH: Biogas Supplying System for Biogas/Diesel Dual-Fuel Engine. Review Science and Technology, The University of Danang, No 3-2008