Combustion: Modelling and Experiments

GATEC

Improving efficiency and reducing environmental pollution are the goals of nearly all scientific research works on combustion published around the world in recent years. So far, the devices using heat have almost been improved in terms of structure and actual motor performance almost achieved the expected ideal value. Therefore, to achieve the above mentioned goals, scientists have focused their research on completing combustion. Combustion is a complicated process directly related to many different scientific fields, such as fluid mechanics, physico-chemical, thermo-dynamics…. So research on combustion requires a perfect support of many industries, especially modeling and experimental measurement engineering.

Combustion process is firstlyrelated to kinetic reaction of hydrocarbon mixtures in air. Substance changing process, leading to change this enthalpy occurs with the formation of a series of intermediates. Depending on the time and the physical and chemical conditions of the combustion environment, these unstable intermediates exist more or less. The intermediates content though is not significant in the final mixture of combustion products, but they are the original chemicals making up of pollutants in the combustion products.

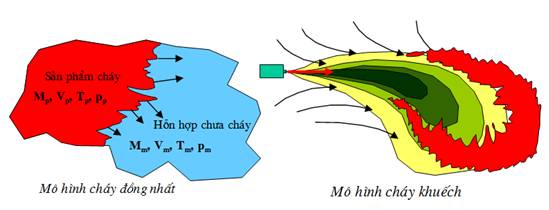

In the combustion with in-advance blended mixture, known mixture components and the inside combustion chamber conditions, the calculation of combustion products is not very complicated. In this case, the two-zone model combined with the semi-experimental expressions for flame spread speed allows calculating the basic quantities of combustion (temperature and pressure) as well as the concentration of the substances in the combustion products. H owever, the problem becomes extremely complicated for diffusion combustion in which oxygen and fuel come from two different sources. To calculate this combustion, the first thing is to determine the local concentration of the fuel and oxygen. The metabolism is done on the oxygen-fuel interfaces, so mixture component distributions occur randomly in a turbulent environment. There are many mathematical models describing diffusion metabolism in this environment, in which the conservation scalar modelhas attracted the most concern of the scientists in recent years. The conservative quantity is neither born nor lost during the combustion. Oxygen-fuel concentration and local combustion temperature are the functions dependent on conservative quantity. The distribution of conservative quantity depends on the probability density function (pdf). In the modeling calculations, we use several different prob

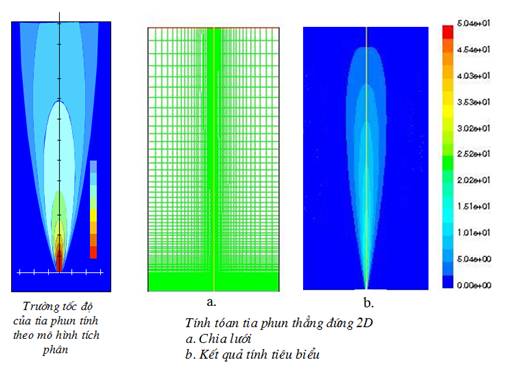

owever, the problem becomes extremely complicated for diffusion combustion in which oxygen and fuel come from two different sources. To calculate this combustion, the first thing is to determine the local concentration of the fuel and oxygen. The metabolism is done on the oxygen-fuel interfaces, so mixture component distributions occur randomly in a turbulent environment. There are many mathematical models describing diffusion metabolism in this environment, in which the conservation scalar modelhas attracted the most concern of the scientists in recent years. The conservative quantity is neither born nor lost during the combustion. Oxygen-fuel concentration and local combustion temperature are the functions dependent on conservative quantity. The distribution of conservative quantity depends on the probability density function (pdf). In the modeling calculations, we use several different prob ability density functions. In the calculation of modeling, various probability density functions are used. The difference of the calculated results is shown in the area with very low fuel density. When determining the local value of the fuel-oxygen concentration, we can calculate the concentration of combusted substances, especially the concentration of pollutants. The application of the model set for combustion in turbulent diffusion jet outside atmosphere into the combustion chamber of the industrial equipment, diesel engines, for example, requires additional system of thermodynamical equations controlling solvent movement in the combustion chamber.

ability density functions. In the calculation of modeling, various probability density functions are used. The difference of the calculated results is shown in the area with very low fuel density. When determining the local value of the fuel-oxygen concentration, we can calculate the concentration of combusted substances, especially the concentration of pollutants. The application of the model set for combustion in turbulent diffusion jet outside atmosphere into the combustion chamber of the industrial equipment, diesel engines, for example, requires additional system of thermodynamical equations controlling solvent movement in the combustion chamber.

Unlike combustion in premixed mixture, diffusion combustion takes place in the areas where the fuel/air ratio reaches the optimal value. The turbulent diffusion jet is divided into multiple sections with close mixture equivalent ratio and this leads to the establishment of multi-zone model in calculating combustion of diesel engines. Thus modeling of the diffusion combustion in addition to the equation controlling (single-phase or multiple-phase)convection-diffusion to close this equation we need turbulent model (e.g. k-epsilon model) – additional models describing diffusion combustion, reaction kinetics formatting substances and thermodynamics equations related to fluid in the combustion chamber (n +1 equation corresponding to temperature and pressure). One such system of equations is very complicated and its solution requires highperformance computing tools. In engineering, with acceptable precision, it is possible to simplify the above equation system by performing them as an analysis in one-dimensional space attached with the models describing the physical phenomenon related to combustion.

More detail

English Translation by GK

_______________________________________________________________