THREE-ZONE MODEL IN CALCULATING

STRATIFIED-CHARGE COMBUSTION PROCESS OF

LPG DIRECT INJECTION SPARK IGNITION ENGINE

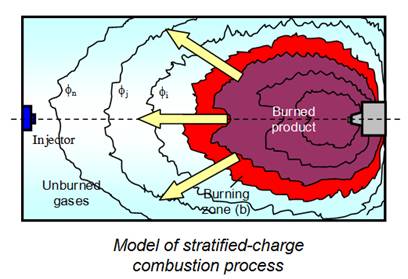

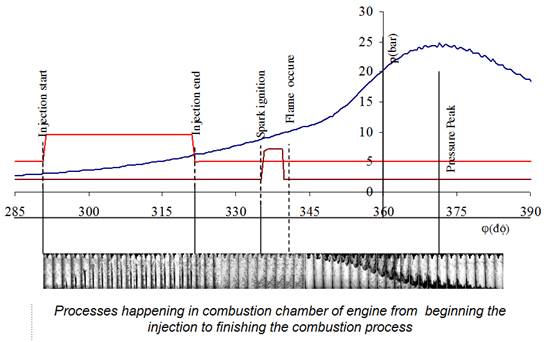

The development and optimalisation of gasoline direct injection (GDI) engine require new experimental methods and specialised mathematical models to analyse the processes occuring in engine’s combustion chamber. The softwares used in researching GDI engine nowadays often base on the softwares that were set up for Diesel engine. The complex stratified mixture in this engine is often calculated by the software of fluid dynamics CFD. The important problem that need to be kept on researching to perfect this engine is calculating the stratified-charge combustion process.

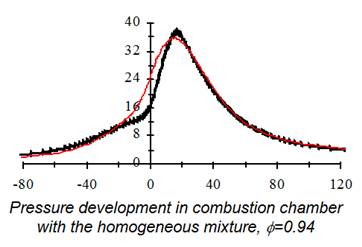

Stratified-charge combustion direct injection spark ignition engine operates at two regulations: combustion regulation of premixed with the engine operates at full load and stratified-charge combustion regulation while the engine operates at low load. Therefore, calculating the combustion process in full load event is similar to calculating traditional spark ignition engine. In this case, we can use the two-zone model that was established to calculate the combustion process of premixed.

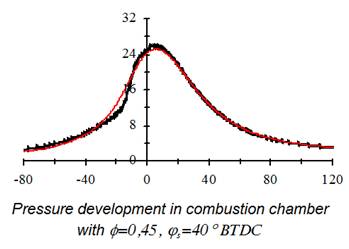

In stratified-charge combustion condition, because of the unhomogeneous mixture, calculating due to that model is unsuitable. On the other hand, the stratified-charge combustion process can’t also apply the multi-zone diffusion cumbustion model of Diesel engine because it happens when the injection process finished while fuel has not diffused equally in the space of combustion chamber yet. Therefore, establishing suitably appropriate mathematical model to calculate the stratified-charge combustion process is very necessary in researching GDI engine in general and stratified-charge combustion LPG direct injection spark ignition engine in particular.

For detail, click here