Congratulations!

New Professor TRAN VAN NAM

GATEC Member

Professor Nam graduated from Danang University of Technology in the major of Mechanical Engineering in 1981. He studied the Master program and got the Degree of Master of science in Osaka Prefecture University, Japan in 1992. He did his PhD research from 1994 to 1997 and got the PhD Degree in 1997 in The University of Danang, Vietnam

Prof. Nam is currently President of the University of Danang.

Prof. Nam is one of GATEC’s founders.

Professor Tran Van NamThree main research approaches:

- Study on the combustion process and the formation of pollutants in internal combustion engine’s emissions.

- Study on the using gas fuels, recycled fuels in internal combustion engine.

- Develop engine’s experimental system in accordance with Vietnam’s researching condition.

Specific Research Areas:

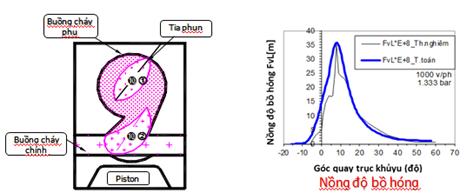

- Diesel engine:Study on theory and implement the experiment of soot formation in combustion process of diesel engine.

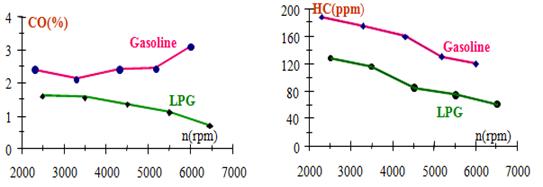

- Spark ignition engine:Study on stratified – charge combustion process in lean burn mixture; study on developing the technology to transfer automobile and motorcycle’s engine from using gasoline into using LPG

- Engine using recycled fuels:study on the combustion process of biogas mixture in dual fuel biogas-diesel engine and in biogas spark ignition engine improved from the engine using traditional liquid fuels

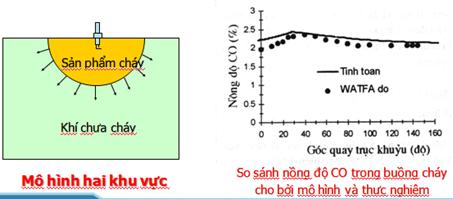

- Develop the calculating modelof the combusiton process and pollutants emission’s formation in combustion process, build the combustion model of diffusive flame, combustion model of spark ignition engine and diesel engine, apply FLUENT software in calculating and simulating the combustion combustion process of dual fuel biogas-diesel engine.

- Develop experimental tools for the stream:research and develop two color method to measure burning temperature and soot concentration; using laser Doppler speedometer to analyze injection and diffusive flame; regenerate from traditional engine’s dynamometer to the one automatically connected to computer system, install mobile engine’s dynamometer serving the researching on biogas engine at biogas fuel manufacturing site.

The main results of research:

– The results of simulations and experiments showed that the concentration of soot in diesel engine increased in areas of high temperature and richer mixture. Therefore reducing soot emissions need to change operational principles of combustion process for compression ignition engine. Dual fuel engine uses homogeneous charge, ignition priming jet diesel consistent with this goal.

– Use of liquefied petroleum gas LPG as an alternative to traditional gasoline can reduce the 80% level of emissions of pollutants such as CO, HC. Experiment shows motorcycle powered by LPG save about 40% energy since the combustion with fuel takes place more perfect than with liquid fuel. Lightweight kit can be made to make traditional motorcycle running on LPG.

– Software modeling combustion and pollutants formation is established based on the reaction thermodynamics and fluid dynamics, although no calculation is made in detail for the combustion process, but it is simple, easy to apply and gives us the forecast of the average value of the physical-chemical quantity of the combustion process, which is useful in engineering.

– Overall fluid dynamics software FLUENT can be applied to calculate combustion process in traditional engines as well as in engines using renewable fuel after upgrading some modules of the software.

– Biogas is an abundant renewable fuel source in our country. Due to the presence of CO2, the biogas combustion is slower than traditional fuels. To increase the efficiency of biogas combustion in internal combustion engines we have to increase the advanced ignition angle or injection advanced angle when the composition of CH4 in biogas reduces and/ or when the engine speed increases. Experiment shows that a 1m3 biogas produced on the average 1kWh electricity.

– In the present context we can manufacture and install experimental biogas engine with high accuracy and automation to conduct engine testing in the fuel production facilities

Concrete applications:

– Manufacture, installation and exportation of accessories transferring traditional motorcycle in running on both gasoline/LPG

– Research on non-traditional fuel resources: LPG, biogas…

– LPG Kit for motorcycle

– LPG Kit for automobile

– Supply LPG system for taxi in Danang City

– Production and commercialization of accessories kits GATEC 20 and GATEC 21 to convert diesel and gasoline engines to biogas running engines

– Design completely compact diesel/biogas-diesel engines, based on Vikyno EV2600-NB engine. A contract with the factory has been made and plans for mass production are in study.