Fuel-Air Equivalence Ratio Measurement System for Biogas-Diesel Dual Engine

Report of Master of Science

Defended on 27 December 2014, at The University of Danang

by Võ Anh Vũ

GATEC-Research Team on Biogas Engine

Abstract

This is a contribution to research of development of a control system for biogas-diesel dual fuel engine base on the research of effects of equivalence ratio on engine performance.

The main content of the research focused on the development of a fuel-air equivalence ratio measrement system. The system is composed by two hot wire flow sensors of Mazda car mounted on biogas and air pipes. Output of the sensors is transfered to computer with help of analogue/digital card and Labview software.

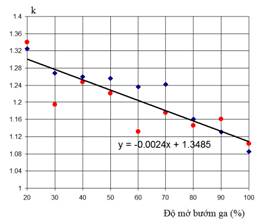

The sensors are calibrated by classical flowmeter for determining relationship E=f(Q). After mounting the system on engine, the calibration of equivalence ratio is carried out by direct analysis of mixture compositions in downstream of the mixer. Coefficient of adjustment k is established in function of biogas valve opening.

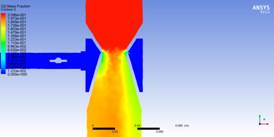

Simulation of mixing process is carried out by CFD Software FLUENT. Experimental data is then compared with simulation data at different operating conditions. The results show that the equivalence ratio given by simulation is quiet coherent with that obtained by experiment. So we can predict the variation of equivalence ratio at different operation conditions of the engine by simulation. The operation map describing the variation of performance of engine with equivalence ratio can be then established. This is necessary document to set up biogas engine control system. Full report: click here

Fig. 1: Display of control monitor Fig. 2: Equivalence Ratio Measurement System

Fig. 3: Coefficient adjustment Fig. 4: Experimental results

Fig. 5: Velocity field Fig. 6: Oxygen concentration

Fig. 7: Comparison experiment/simulation